The McGraw 3 Gallon air compressor is a small, light in weight (16.32 lb | 7.40 kg) unit that is perfect for small tasks like inflating sports equipment and automobile tires. It is easy to move around because it is light. With the compressor, we’ve started doing home projects ourselves.

If you’re looking for an air compressor that packs a powerful punch, the McGraw may not be right for you. Its 1/3 HP motor and 3-gallon tank can’t maintain high pressure, so it won’t work with some power tools. However, it still has a flow capacity of 0.6 CFM which should cover most applications just fine.

There are some other drawbacks to the McGraw air compressor compared to other units on the market. One such drawback is idle air loss; this means that when not in use, the machine will slowly lose pressure until it needs to be refilled again – something that may be annoying for users who often don’t have time to do so frequently throughout their day-to-day lives.

Another downside of the machine is its noise level (84dB noise level rating); while in operation, it emits a loud, high-pitched sound that can be disturbing indoors. Therefore, it’s better to use it outside.

All in all, however, the McGraw air compressor Still remains a useful tool for those vying for either portability or affordability over power output ability. Overall, the McGraw air compressor represents an excellent value and would make a great addition to any home workshop or garage.

McGraw 3 Gallon Air Compressor for Painting

Even if you can use the Mcgraw air compressor for small painting jobs, it’ll be exhausting to use it for a longer time. Since the tank size is just 3 gallons and the motor is 1/3 HP, it doesn’t generate high air pressure. This pressure is not enough for professional work.

When using it for a longer time, the pressure lowers, and it’s really exhausting to do painting jobs for long hours with this.

Pros

- The unit is perfect for inflating sports equipment and automobile tires.

- It is easy to move around because it is light.

- With inflation, we’ve started doing home projects ourselves.

- The 1/3 HP motor can’t maintain volume or pressure, but it is still a durable and portable compressor.

Cons

- The compressor is loud, and the sound is also high-pitched. So, the sound bounces off the garage walls and gives me a headache.

- This 1/3 HP motor can’t maintain high pressure.

- It takes more time to build the pressure in the tank than the brands like DeWalt.

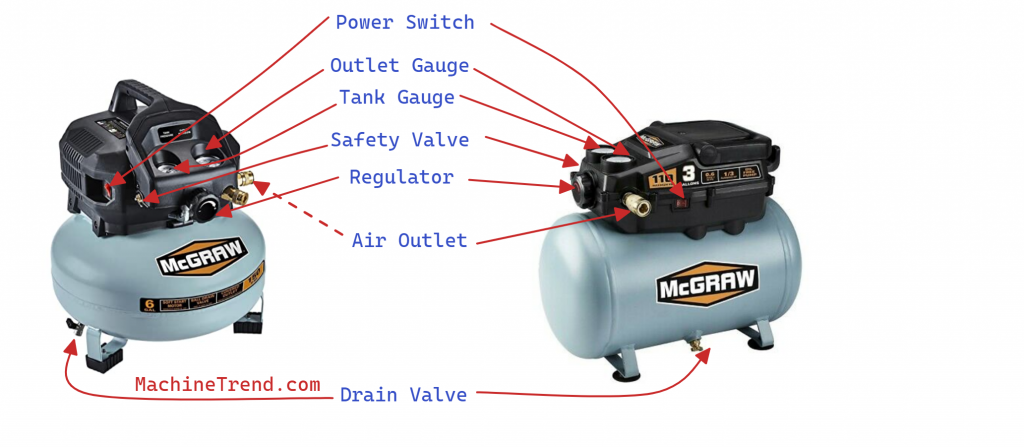

Parts of the Air Compressor

Recommended Minimum Wire Gauge For Extension Cords

| Nameplate FLA | 25’ | 50’ | 100’ | 150’ |

| 0 – 6 | 18 | 16 | 16 | 14 |

| 6 – 10 | 18 | 16 | N/A | N/A |

| 10 – 12 | 16 | 16 | N/A | N/A |

| 12 – 16 | 14 | 12 | N/A | N/A |

Nameplate FLA: Nameplate Full Load Amperes

McGraw Air Compressor VS Harbor Freight’s Air Compressor

When comparing McGraw air compressors with Harbor Freight’s air compressors, I believe that McGraw is better. In my opinion, this is due to the fact that McGraw compressors tend to be more durable and offer better performance than their Harbor Freight counterparts.

Troubleshooting Guide

The compressor does not start or restart

If your McGraw air compressor doesn’t start or restart, there are several possible causes.

Pressurized Tank

If your McGraw air compressor doesn’t start or restart, there could be a few different causes. First, make sure that the tank is not already pressurized – if they are, the compressor will simply start when needed.

Power Cord

Next, check to see that the power cord is plugged in properly. If it’s not, plug it in securely and try again. And make sure that you’re using the correct power supply for your particular model of compressor. Inspect the cord for any damage and replace it if necessary.

The compatible plug and the outlet of the McGraw air compressor is a 125V AC 3-prong plug and outlet. But it may change with the country. So, check the sales page of your model to know the required model.

Further, if the power cord plug provided with the compressor is modified, it may no longer be compatible with the compressor and could cause an issue.

Power Supply

The Mcgraw air compressor may fail to start or restart due to an incorrect power supply. It is important to check that the circuit matches the specific requirements of your Mcgraw air compressor model. If the power source does not meet these requirements, this can lead to impaired function or even complete failure of the device.

Overload Switch

It is common for the thermal overload switch to trip and cause the compressor not to start up due again to overheating. To fix this, turn off the compressor and wait for it to cool down. Once cooled, press the reset button in order to resume operation.

Trip Switch

Another potential problem could be that the power supply circuit has either blown a fuse or tripped. In this case, you’ll need to reset the circuit or replace the fuse before proceeding. It’s also a good idea to check for low voltage conditions, as this can cause problems with starting up compressors. If necessary, disconnect other electrical appliances from the same circuit or move the compressor to its own dedicated circuit.

Wire Diameter and the Length of the Extension Cord

If your air compressor doesn’t start or restart, it could also be because the cord wire size is too small. Use a larger diameter or shorter extension cord, or eliminate the extension cord altogether to fix the issue.

The compressor builds pressure too slowly

If your McGraw air compressor isn’t building pressure as quickly as it should be, there are a few possible reasons. One is that the power supply doesn’t match the requirements of the compressor.

Another possibility is that working conditions are too cold for proper function. Additionally, loose fittings can cause escaping air and prevent pressurization – check all fittings for leaks and tighten accordingly.

If none of these seems to be the issue, it may be that safety valves are leaking; in this case, replace them with an identical valve with the same rating.

Compressor not building enough air pressure

The air compressor may not be building enough pressure due to a few different reasons. The first reason could be that the air filters need to be cleaned or replaced.

It may also be due to a problem with the check valve. This valve is responsible for allowing air to flow into the compressor while preventing backflow. If it becomes clogged or damaged, it can prevent the necessary amount of air from entering the system, resulting in lower than normal pressure levels. To fix this issue, you’ll need to have a technician clean or replace the check valve as needed.

Other than that, the compressor might not be large enough for the job required of it- in this case, checking if the accessory CFM is met by the compressor will help determine whether you should seek out a larger model.

One possibility is that there are loose fittings somewhere in the system. This can cause air leaks, which will reduce overall pressure. To fix this, check all fittings and connections for leaks using a soap solution. Once you’ve found the leaky areas, tighten the fittings but be careful not to overtighten them.

The problem may be with the hose or hose connections. If they’re too narrow, replace them with wider ones. Higher altitudes can also reduce air output, so if you’re in a high-altitude area, you’ll need a compressor with greater output.

Overheating

One potential cause of an air compressor overheating is loose fittings. If the fittings are not secure, air can leak out, causing the compressor to work harder and overheat.

Another possibility is that the compressor is not large enough for the job it is being asked to do. If too much airflow is required by the accessory, the unit will struggle to keep up and may overheat as a result.

Solutions include reducing pressure and checking all connections for leaks with a soap solution; if needed, tighten them slowly so as not to over-tighten them.

In cases where a larger CFM output is necessary, use a different, more powerful compressor rather than continuing to try and force. The current one is to work beyond its capabilities.